Why is Punch and die clearance important in machinery?

Why is Punch and die clearance important in machinery?

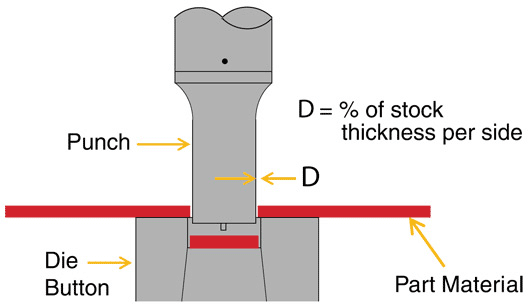

Correct punch and die clearance is crucial during the punching operation. Proper clearance produce a hole with approximately the top one third measuring the size of the punch and the bottom two thirds flaring to the approximate inside diameter of the die.

Insufficient clearance will usually result in a secondary shear on the material, producing additional wear on the punch.

On the other hand, excessive clearance may produce a large flare as well as a burr on the bottom side of the material. Material “roll-over” may also happen along the top edge of the hole, and may result in the punch’s sharp edge to break down quickly.

There is no exact science for determining the proper clearance between the punch and die. What may work for one particular type of material may be different for another.

Follow the clearance chart below for the best results when punching mild steel.

Punching Features

It is the most cheap process of making holes in strip or sheet metal for average to high fabrication.

It is a quick process.

It is able to create multiple shaped holes.

Punches and dies are usually fabricated from conventional tool steel or carbides.

It creates a burnished region roll-over, and die break on sidewall of the resulting hole.

Based in China, JLS has been specializing in precision die punches and buttons, bushings, ejector pin, core pins, die buttons according to CAD drawings for 20 years.

#carbidepunch